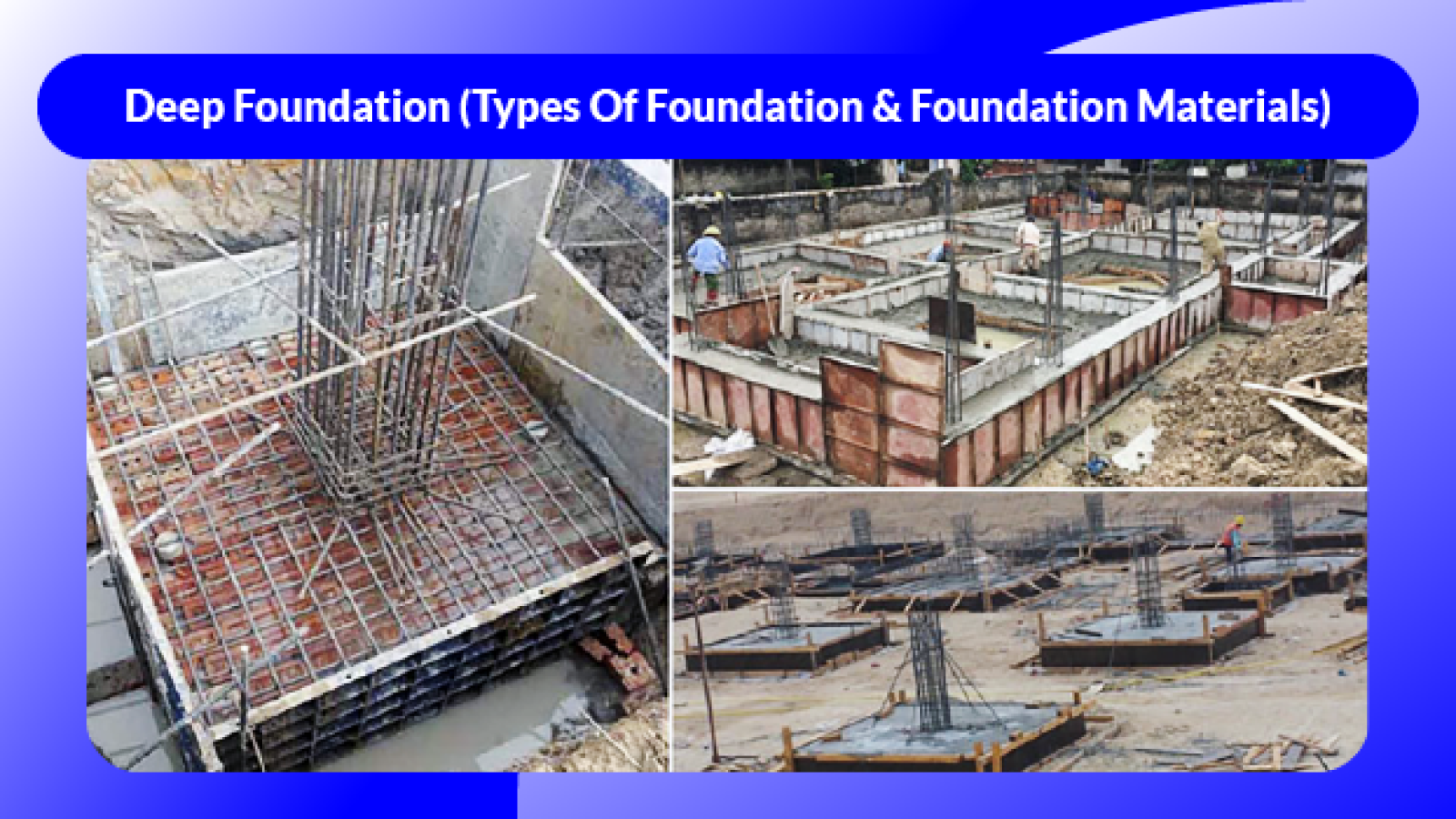

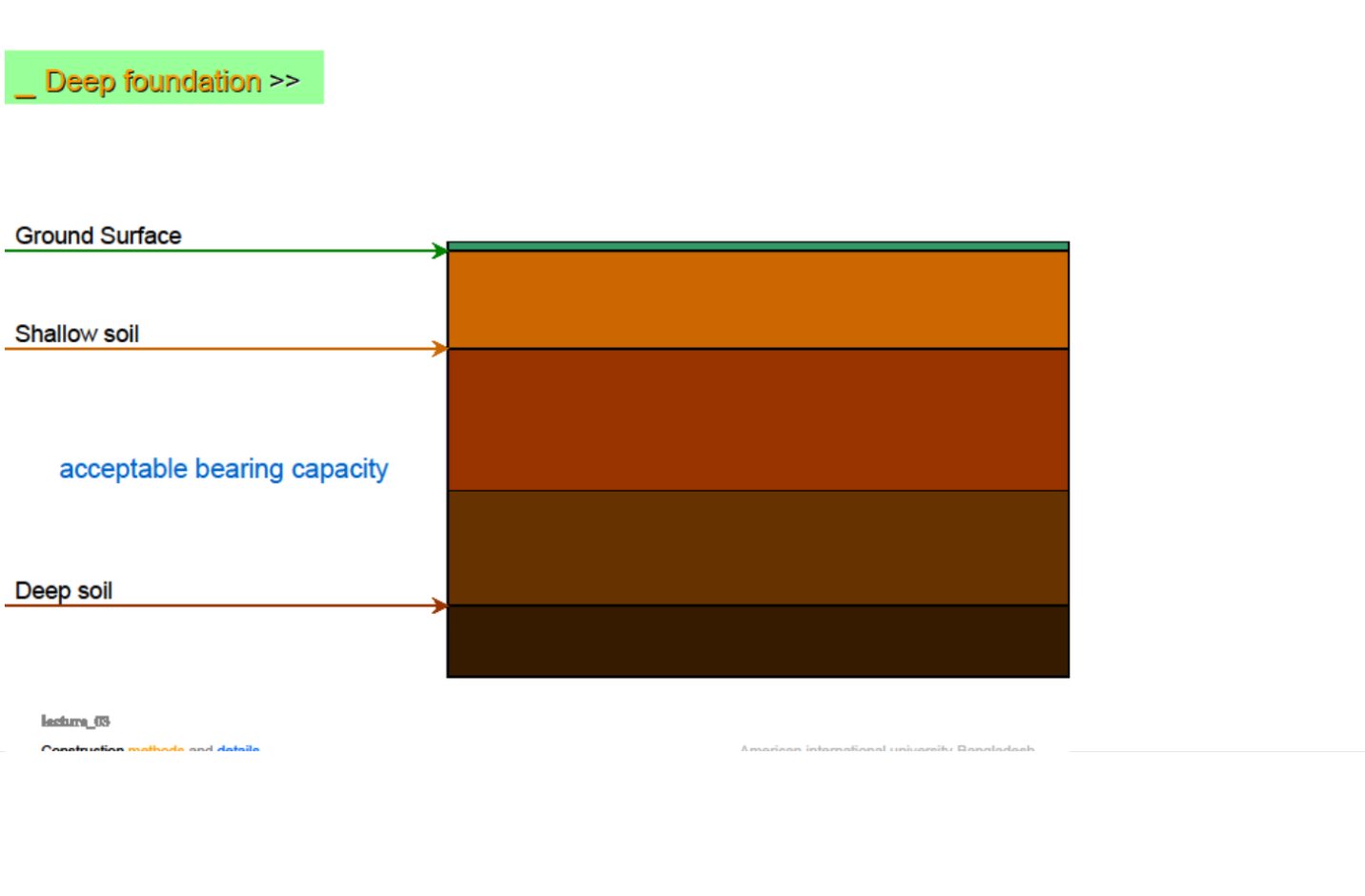

- Deep foundations are those founding too deeply below the finished ground surface for their base bearing capacity to be affected by surface conditions, this is usually at depths >3 m below finished ground level.

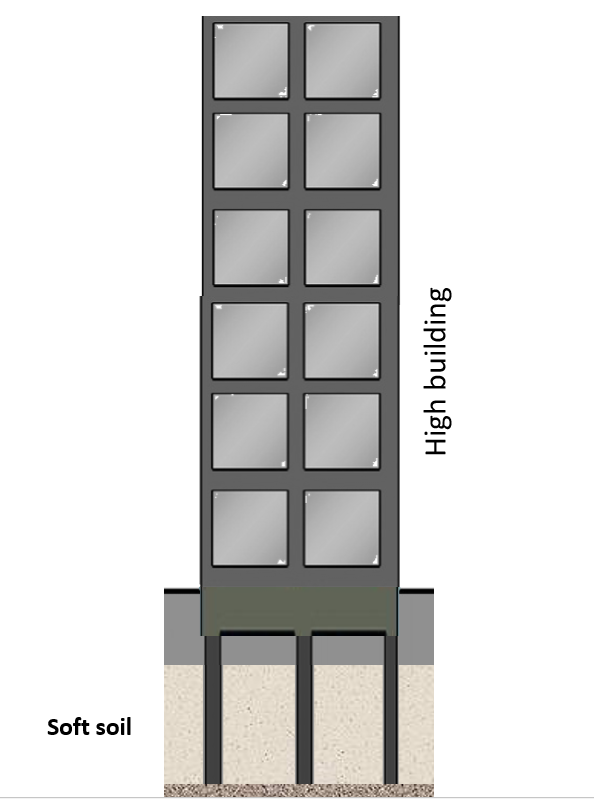

- Deep foundations are used when there are weak soils near the surface or when loads are very high, such as very large skyscrapers.

- Deep foundations derive their support from deeper soils or bedrock.

TYPES OF DEEP FOUNDATIONS

1.PILE FOUNDATIONS:

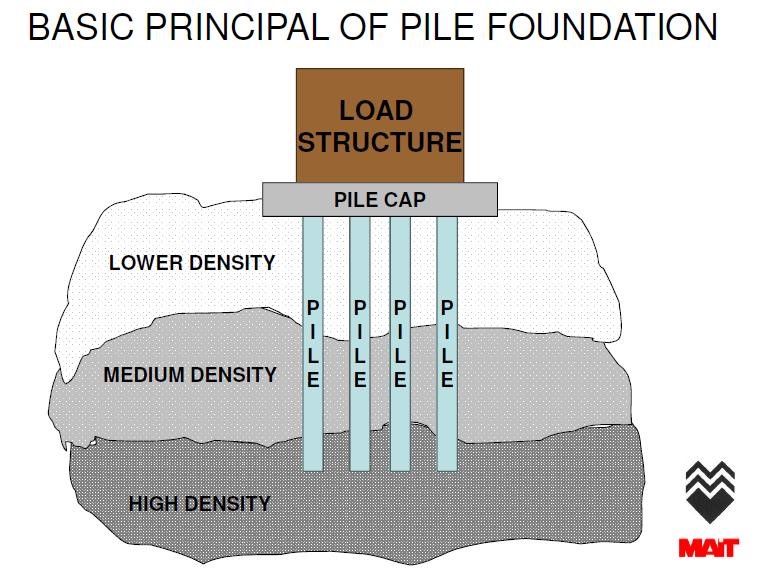

Piles are relatively long, slender members that transmit foundation loads through soil strata of low bearing capacity to deeper soil or rock strata having a high bearing capacity.

Pile caps are thick slabs used to tie a group of piles together to support and transmit column loads to the piles.

- PILE Foundation :

In addition to supporting structures, piles are also used to anchor structures against uplift forces and also to assist structures in resisting lateral and overturning forces.

Types of Piles:

a. Based on method of installation:

- Driven piles (displacement piles): made of steel, pre-stressed concrete, timber, or composite.

- Bored piles (replacement piles): Augured and cast in-situ.

- Other piles: Sheet-pile, Micro piles, Suction Piles, Vibrated Stone Columns, Anchor Piles, Fender piles, Batter Piles etc.

b. Based on method of Materials: Steel, Timber, Plastic, Composite

c. Based on installation technique :

- Cast in situ Piles

- Precast Piles

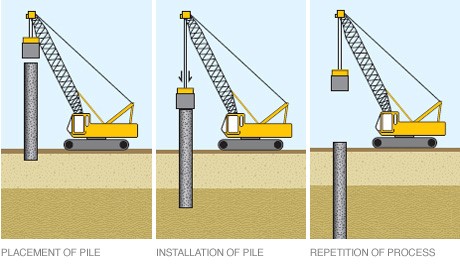

DRIVEN OR DISPLACEMENT PILES

Advantages:

- May be inspected for quality and soundness before driving

- Not liable to squeezing or necking

- Construction not affected by ground water

- Can be left protruding above G.L.(useful in marine structures)

- Can withstand high bending and tensile stressed

- Can be driven in long lengths

Disadvantages:

- Unjointed types cannot easily be varied in length.

- May break during driving

- Uneconomic if the design is governed by driving stresses rather than working stresses

- Noise and vibration during driving

- Displacement of soil may affect adjacent structures

- Cannot be driven in situations of low head room

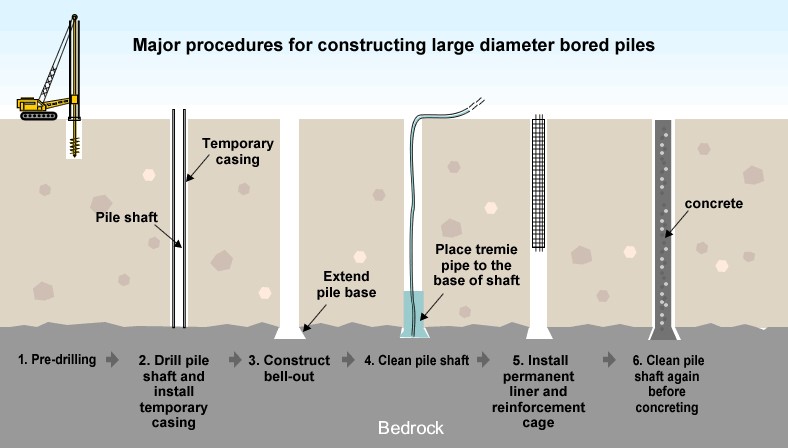

BORED OR REPLACEMENT PILES

Advantages:

- Length can be varied, very long lengths possible

- Removed soil can be compared with design data

- Penetration tests can be carried out in boreholes

- Very large bases can be possibly formed

- Drilling tools can break up boulders, obstructions,

- Little noise and vibration during construction

- No ground heaves

Disadvantages:

- Piles liable to squeezing and necking in soft soil

- Special techniques required for concreting in water bearing ground

- Concrete cannot be inspected after installation

- Enlarged bases cannot be formed in collapsible soil

- Cannot be easily extended above ground

- Boring may cause instability and settlement of adjacent structures

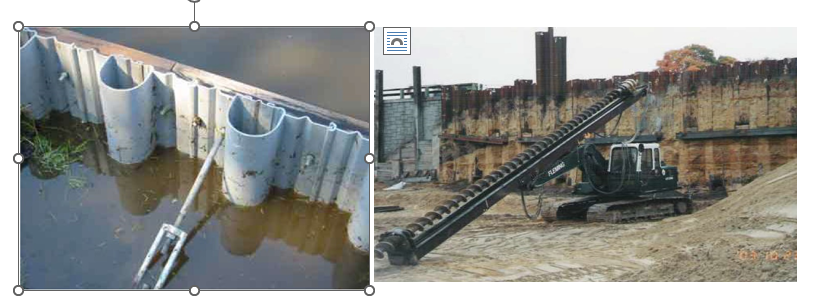

OTHER PILES _ Sheet Piles :

It is rarely used for vertical support rather it is preferable for retaining soil that is liable to escape the area required for some foundation and protect it from the action of running water of leakage.

OTHER PILES _ Anchor Piles :

Provide anchorage against horizontal pull from sheet piling.

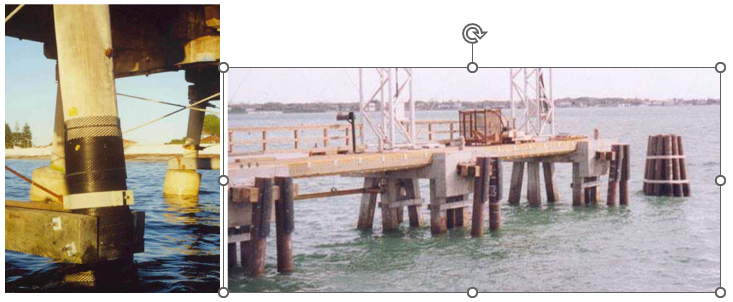

OTHER PILES _ Fender Piles :

A pile driven into the bottom of a body of water near a berth to protect the pier or jetty against damage by incoming vessels.

OTHER PILES _ Batter Piles :

A pile driven at an angle to the vertical.

02. CAISSONS :

The word caisson is derived from Latin capsa [1] which means box or case.

Caissons denotes watertight structures which are constructed in connection with the excavation for foundations of bridges, piers, abutments in river and lake dock structure, foreshore protection etc. The caisson remains in its pose and thus ultimately becomes as integral parts of the permanent structure. It can be made up of wood, steel or reinforced concrete etc.

When Caisson is Required :

- When the soil contains large boulders, which obstruct penetration of piles.

- When a massive substructure is required to extend to or below the rear bed to provide resistance against destructive forces due to floating objects and score etc.

- When the foundation is subjected to a large lateral load.

- When the depth of water level in the river and sea is high.

- When there are river forces included in the load compositions.

- When the load is needed to carry at the end, caissons are preferred.

- When the present groundwater level is aggressive inflow, caissons are suitable.

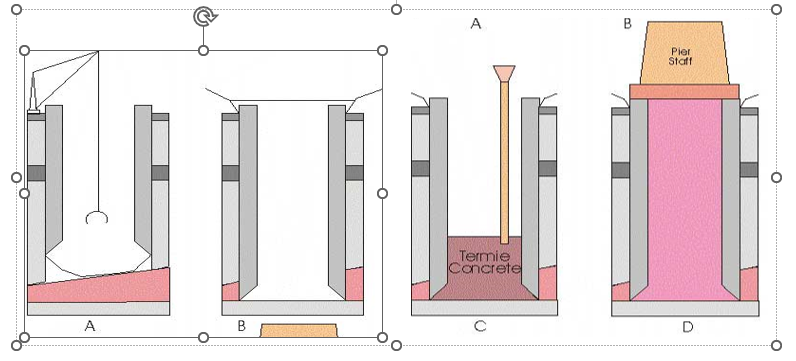

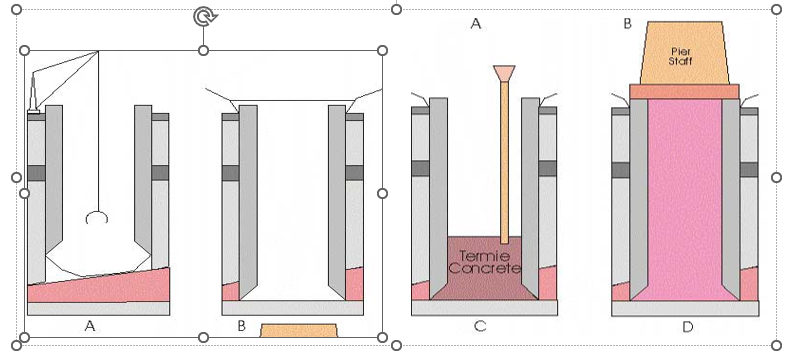

CAISSONS _ Construction Diagram

Advantages:

- Caissons are economic.

- It is environment-friendly. There are slightly less sound pollution and reduced vibration.

- It is easily adaptable to varying underwater soil conditions.

- Caisson has high horizontal and lateral loading capacity.

- Minimum handling equipment is required for placement of reinforcement cage.

- It is sometimes used in types of soils where driving pile could not penetrate.

- Caissons can be reached to great depths.

- There is a direct and effortless way to go to the bottom of caissons to remove any kind of obstruction.

- Quality control of pneumatic caisson is good as it is built on dry conditions.

Disadvantages:

- The construction procedure is extremely sensitive and troublesome.

- It is not good for polluted sites.

- It needs expert engineers to design the construction.

- There is lack of qualified workers.

- The workers may suffer from giddiness, breaking of eardrums, bursting of blood vessels in the nose or ears and end up in paralytic death which is known as caisson disease.

- As the pouring of concrete is done underwater, it may not be satisfactory.

- The help of divers may be required.

COFFER DAM :

A cofferdam is a temporary structure designed to keep water and/or soil out of the excavation in which a bridge pier or other structure is built. When construction must take place below the water level, a cofferdam is built to give workers a dry work environment. Sheet piling is driven around the work site, seal concrete is placed into the bottom to prevent water from seeping in from underneath the sheet piling, and the water is pumped out.

The word “cofferdam” comes from “coffer” meaning box, in other words a dam in the shape of a box.

COMPONENTS :

- Sheet piling

- Bracing frame

- Concrete seal

- Bearing piles

ADVANTAGES :

- Allows excavation and construction of structures in otherwise poor environment .

- Provides safe environment to work

- Contractors typically have design responsibility

- Steel sheet piles are easily installed and removed

- Materials can typically be reused on other projects

DIFFERENCE BETWEEN COOFER DAM AND CAISSONS :

Caissons are the permanent structures and also water tight boxes which act as a substructure in the main construction.

Where as cofferdams are also water tight boxes but these are temporary structures built during under water constructions.

Photo (All) – Google

Writer

Shanta Islam

Instructor

AIDT & Architecture Department

Daffodil Polytechnic Institute